What is the DTF?

DTF (Direct To Film) is an innovative textile personalisation technique which aims to produce colour prints on a film and then transfer them directly onto fabric. Whether it is polyester, cotton, silk or synthetic fibres, the DTF printing technique can be adapted to all your materials. Since its release in 2020, this innovative process is a real revolution in the textile personalisation market!

Requirements for printing in DTF

As with any textile design and printing process, you will need equipment to get started. We offer you complete DTF solutions with all the necessary equipment.

We offer training as well as installation on the purchase of a DTF Kit!

The DTF printer You will obviously need a DTF printer. There are several models of printers that you can choose from depending on your monthly quantities and needs.

Software : To print, you need software such as Acrorip or digitalactory to manage your artwork and to import it into the printer. Via the software, you will also control the ink level, the size of the visual and all the parameters that allow you to achieve an optimal printing result.

DTF inks: These are pigmented inks, specially designed for DTF printing. The result? Bright, vivid colours, a fine, soft feel, excellent resistance and washout properties, and stretchy, crack-free printing. Our inks are compatible with a wide variety of DTF printers and films.

DTF film: DTF film is essential for printing your graphics. It serves as a "transport" to transfer your visuals onto your textile supports.

Hot melt powder : DTF printing powder is white or black in colour. It acts as an adhesive material that binds the colour pigments of the print to the fabric fibres. Black powder is mainly used on dark textiles to avoid the appearance of slight traces of adhesive residue.

Curing oven : This allows the visual to harden once it has been powdered. After this step, your hardened visual will be ready to be transferred to the textile support.

heat press The heat press is used to transfer the visuals from the film to your textile support.

Not sure if you want to invest? Order the DTF Ready to Press! Send us your files, we take care of everything. All you have to do is press your visuals onto the media of your choice!

Find the Prêt à Presser on our website!

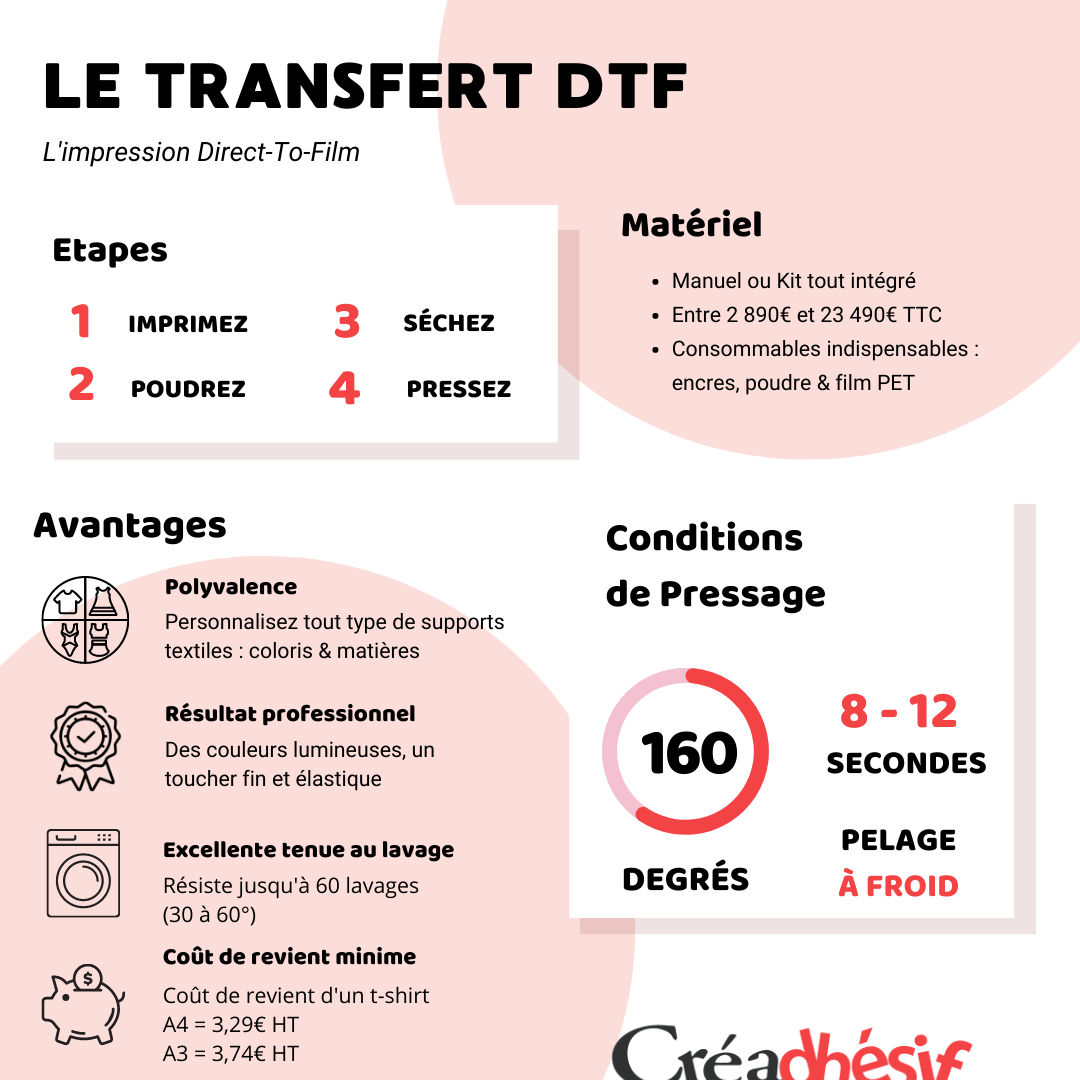

Print DTF in 4 steps:

Step 1: Set up and start printing. The printer takes care of everything, the colours will be printed first and then a layer of white will be applied on top.

Step 2: Apply hot melt powder to the printed visual.

The application of the powder can be automatic if you have a powder applicator connected to your DTF printer. If this is not the case you must apply the powder to the film evenly while the print is still wet.

/Do not touch the ink while it is still wet.

Step 3: In this step the aim is to harden the hot melt powder by heating the film with your visual on it. To do this you only need a curing oven that you can connect directly to your printer (depending on the model) so that it is automatic.

Tip: If you do not have an oven, you can use the heat press. Without putting the top tray in contact with your film, heat it for 2min at 160-170°C with a gap of 4 to 7mm.

Step 4: In this last step, you can press the visual onto your substrate with different pressing conditions depending on the material of the textile you are using:

- - Cotton, 8 to 12 seconds at 160°C

- - Polyester, 50 seconds at 140°C

Press and then let your textile cool down to peel.

The Benefits

Le DTF dispose de nombreux avantages par rapport à ses concurrents comme le DTG, le flocage ou encore la sérigraphie. Le procédé est plus rapide et plus simple que ces différentes techniques. Vous verrez ensuite disparaître les étapes de découpe et d'échenillage (Flocage) l'étape de pré-traitement (DTG).

DTF printing also reproduces photos and drawings in photographic quality with bright, vibrant colours and a very professional result.

You will also notice a real difference in feel compared to other printing techniques. DTF offers a fine and much lighter finish, close to that of screen printing or sublimation. The elasticity is also a strong point of DTF graphics, you can stretch your textile without fear of the graphic cracking or tearing.

Créadhésif currently offers quality DTF inks that are compatible with most DTF printers. Our inks are known in particular for their effectiveness in bringing out the most delicate colours on light and dark coloured fabrics. The white provides the appropriate density for the printed colours with optimum ink consumption.

Generally speaking, it can be said that DTF printing allows us to free ourselves from most of the constraints that are often encountered in other textile printing techniques. The versatility of the textile materials on which it is possible to work is a real advantage. The cost of DTF printing is the lowest on the market (0.50 € ex. VAT for an A4 format) thus offering a higher profit margin. In conclusion, DTF printing can be considered as the best solution for textile marking.

Find our costing sheets on our website!

Need more information on DTF? We offer free online training (webinars) and exclusive videos on Youtube :

- - Webinar - The DTF Technique

- - Webinar - DTF Ready-to-Press

- - Créa'TV - What is the DTF transfer?

- - Créa'TV - Presentation DTF Kit 4 heads 30cm format

- - Créa'TV - Interview : The DTF in 13 questions

- - Créa'Express - 1 min & 4 steps to personalise in DTF!

- - Créa'Tuto - Making a DTF transfer marking

A special DTF Facebook Live is also available on our Page, click on this link to discover it!

To register for Webinars, online training!

To access the Youtubetutorials

To access our Podcasts

Please contact us if you have any questions about customisation in DTF on 01 34 33 01 55.

To discover our tips, advice and news, subscribe to our Youtube channel and follow us on our social networks, Instagram, Facebook, LinkedIn and TikTok to keep up with our news and access other interesting information on DTF and many other customisation techniques.

See you soon,

The Team Créadhésif